There is one thing we can probably all agree on: the fast fashion industry still has a long way to go regarding sustainability.

Marlene Hohn

PhD candidate at ESCP Business School (Berlin campus)

Christian Durach

Professor at ESCP Business School (Berlin campus)

Formerly presenting two seasons per year, the industry has turned into a fast-paced, globally‑spread production system that offers fresh looks every other week. The societal costs of having new products designed, produced, and shipped within such a short timeframe are substantial.

A production system that has become ‘degenerate’

As Nicolai Peitersen points out, fashion production creates vast amounts of wastewater and other wasteful materials while the increased consumption of fashion results in an equally steep increase in fashion waste – the recyclability of which is unthinkably low.

Chile’s desert dumping ground for fashion leftovers, or tragedies like the Rana Plaza factories’ collapse in 2014, illustrate how degenerate the fashion production system has become – not least with respect to the working conditions on the shop floors.

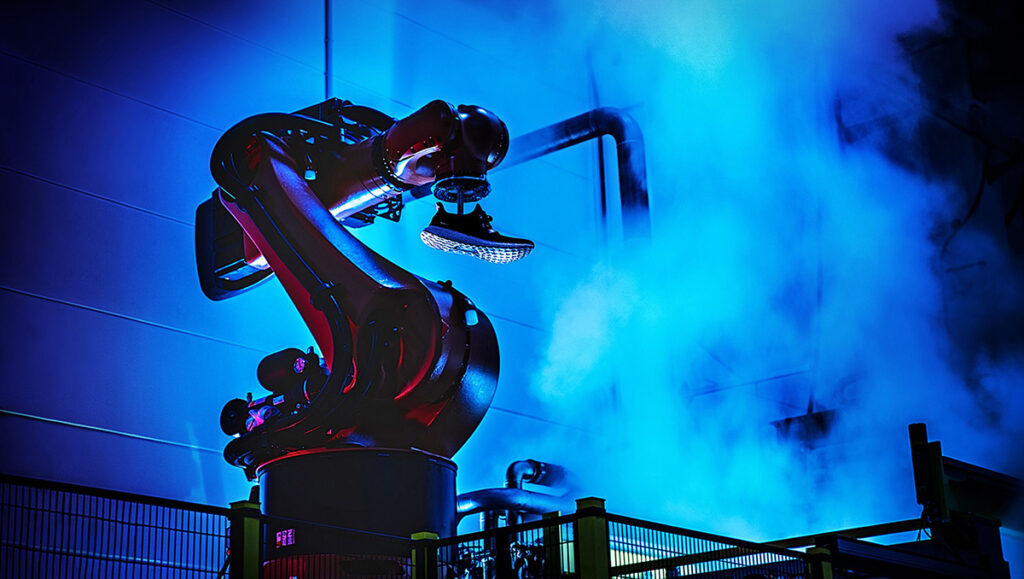

The co-founder of Wikifactory, who also co-authored The Ethical Economy, suggests that innovative technologies like 3D printing, also called ‘additive manufacturing,’ present a promising solution for these issues. This assessment is primarily based on the author’s focus on the environmental sustainability of production and transportation processes.

In this regard, 3D printing’s emergence is believed to make fashion production more efficient while it may, at the same time, provide opportunities to move production back to main consumer markets in Europe or North America. Both developments stand to significantly reduce the costs and emissions in this industry.

While our findings support the notion that 3D printing is likely to reshape where and how fashion is produced, they suggest that these changes will do little to solve the social sustainability issues in fashion production.

Yet, the results of our recent research project paint a different picture of the social sustainability implications of 3D printing in the fashion industry. While our findings support the notion that this technology is likely to reshape where and how fashion is produced, they suggest that these changes will do little to solve the social sustainability issues in fashion production.

Why? To understand why the potential economic benefits of 3D printing use in fashion production are unlikely to result in increased social sustainability, it is pertinent to consider the governance structures prevalent in the fashion industry. In typical fashion supply chains, stark power differentials prevail between retail firms like Adidas, Zara or Puma, and their suppliers, meaning that the former strongly influence where and how apparel is produced.

The potential of reinstating fashion as ‘an appreciated art form’

Thus, one should remain sceptical about who would reap the benefits of 3D printing’s emergence. Our research suggests that more powerful actors in the downstream supply chain will capture any resulting economic gains. In consequence, the detrimental working conditions in mass fashion production would remain largely unchanged.

Still, one silver lining could lie in what Peitersen describes as reconceiving fashion as “an appreciated art form.” If the innovativeness of 3D printing would incite the big fashion companies to move away from their current low-cost, (ultra-)fast-fashion strategy, the positive impact on environmental as well as social sustainability would be gigantic. The technology’s potential for creating personalised fashion items for the masses could just be the incentive they need.

This post gives the views of its author, not the position of ESCP Business School.